Cleaning Products, Educational, Food Service/Processing

Smooth Moves: Getting Rid of Limescale in Your Commercial Kitchen

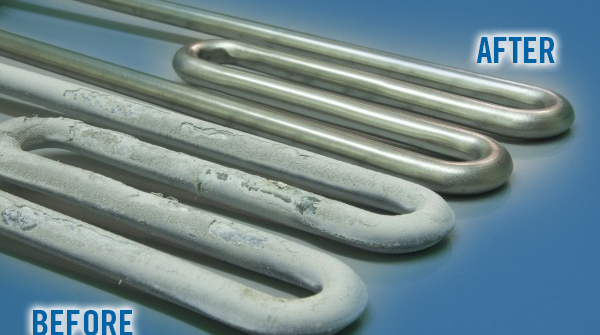

It’s a problem all commercial and industrial kitchens face – white, crusty deposits in and around dishmachines, steam tables, and equipment that come in contact with water supplies. Hard water deposits, also known as limescale, not only prevent kitchen areas from looking their best but can also keep equipment from functioning at optimum levels. Fortunately, specially-formulated chemicals called delimers and descalers are available to combat this problem and help keep kitchens looking great and operating smoothly. But how do you know if you are using the proper type of delimer for your operation?

What Exactly is Limescale?

Limescale is a type of hard water deposit. All water sources are considered either “hard” or “soft,” a designation determined by the amount of naturally occurring minerals that are present, including lime, calcium, iron and magnesium. Hard water contains more of these dissolved salts and minerals. When water evaporates from surfaces it leaves the minerals behind. Since heat accelerates evaporation, kitchen equipment in contact with heated water – dishmachines, steam tables and chafing dishes to name a few – will build limescale the quickest.

Another indication of hard water is a lack of suds or lather from soap and other cleaning products. Hard water interferes with the effectiveness of cleaners. Since impurities don’t easily rinse away, a film remains. Limescale and soap scum are difficult to remove without the use of delimers, and if left untreated will clog dishmachines and other kitchen equipment, or at the very least impair their performance.

How Do Delimers Work?

Delimers dissolve limescale using a formulation of acids and low foam surfactants. Several types of acids can be used, however, the most three most common types of delimers found in commercial kitchens are:

- hydrochloric acid (HCl) based – the most aggressive

- phosphoric acid based – less aggressive

- lactic acid based – least aggressive and therefore considered a “green” delimer

Because limescale minerals are alkaline (or basic) in nature on the pH scale, formulations that are acidic will “neutralize” or dissolve them, leaving behind a clean, smooth surface.

Using Delimers in Commercial Settings

In a commercial kitchen, anything that uses water or comes in contact with water—especially in connection with heat—will need to be delimed periodically, including: dish machines, ice machines, steam tables, chafing dishes, coffee machines, cooking/soup kettles, water faucets and 3-compartment sinks. Choose your delimer based on three primary considerations:

Levels of water hardness are determined by geography of your water source. Test for impurities using a “titration kit.” Results will show whether your supply is soft or hard, as measured by the amount of red (rust/iron) or white (calcium, magnesium) minerals in your water. Geographies with the hardest water may require use of an aggressive, HCl-based delimer, such as D-Lime. While delimers containing HCl are effective in removing rust, they are also harsh and fume, and therefore not recommended for manual use or in spray applications that might aerosolize, as dangerous fumes could spread throughout a kitchen or foodservice operation.

It’s important to evaluate the surface or equipment to be cleaned, making sure the delimer selected will not damage it. In most areas, or when more general cleaning of equipment and appliances is needed, including coffee urns, glasses, fixtures and plastics, a phosphoric acid-based product like Low Foam Delimer will do the trick nicely. Phos delimers are the most common because they are effective on most minerals if given enough time, yet not as dangerous as HCl.

Some buildings or operations require use of green chemicals. If yours is one or if you have any doubts, consider a delimer like e.logical Restore. Recognized as a Safer Choice product by the EPA, this type of delimer is considered the safest amongst the universe of delimers.

Tips for Deliming Your Commercial Kitchen

Keep the following guidelines in mind when selecting and using delimers:

- Unsure if you have hard water? Use a titration kit to determine your exact levels, which are available from most cleaning chemical manufacturers or for purchase directly on the internet. If you have well water you can generally assume it is hard.

- Be sure to follow the manufacturer’s directions when using delimers, especially HCl delimers. ALWAYS wear PPE (personal protective equipment), including safety glasses and gloves.

- Avoid using HCl delimers if using a sprayer. HCl fumes. When used with sprayers the fumes can more easily get into the air (aerosolize) and be dangerous.

- Choose wisely: interior components of dish and ice machines can be sensitive to hydrochloric acid, but water conditions in some areas may require the use of a more aggressive delimer.

- Be advised that HCl in any concentration is not recommended for use with soft metals like aluminum.

- Looking to delime your commercial dish machine? Click here for instructions on deliming high temp and low temp machines.

- Be sure to flush/rinse any delimed surfaces thoroughly, leaving no trace of the product behind.

- Consider an EPA “Safer Choice” product if there is any question about personnel safety or building guidelines.

Don’t let limescale take the shine off your kitchen and food service areas. A little attention and regular maintenance with the right deliming product will keep things clean and bright, and keep your operation in the clear!