How to Choose a Floor Finish

Flooring is expensive and can cost several dollars per square foot to install. Floor finishes, on the other hand, cost less than a penny per square foot and will protect floors from wear and abuse. Choosing the right floor finish for your facility program is the first step to creating and maintaining beautiful floors.

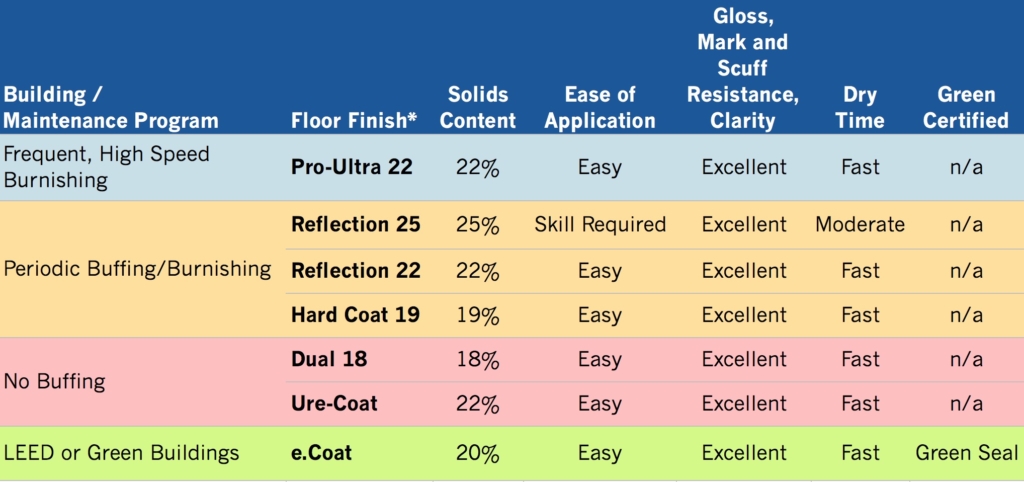

Floor finishes are a balance in compromise …they must be high gloss yet slip resistant, buffable yet mark-resistant, durable, yet easily removed. The attributes that should be evaluated include gloss, hardness, durability, scuff resistance, black mark resistance, slip resistance (for safety), clarity, dry time, and ease of application.

The type of floor equipment used in a program, along with the skill of the labor force and frequency of maintenance, will all be important factors in which finish is recommended. When selecting a floor finish, start by asking these questions…

What type of Floor Maintenance Program do you have?

We categorize floor care programs into 3 buckets based on frequency of buffing. Aspects of these programs may have some overlap between them:

1. Frequent, High Speed Burnishing Program

This usually means burnishing 1-7 times per week, with a propane or electric high speed burnisher. It requires a skilled and trained labor force. If you have this type of program we recommend Pro-Ultra 22 Ultra High Speed Floor Finish.

2. Periodic Buffing Program

Maintenance is performed as often as 1-2 times per week to as little as once per quarter, with a low or high speed electric floor machine. Nyco offers three finishes for the needs of these programs, with varying solids content.

- Reflection 25. With 25% solids, this high solids finish can save a good amount of labor. Higher solids are more challenging to lay down, however, they require fewer coats of finish for the same degree of gloss and protection. High solids finishes also require longer dry time, so for areas with high humidity, high solids finishes may not be the ideal choice.

- Hard Coat 19. In contrast to Reflection 25, Hard Coat 19 is easy to apply and forgiving of skill level. But you will need to apply 5 coats for every 4 coats of Reflection 25. Many floor care professionals know “The Rule of 100,” which says that the number of coats of finish that are needed on a floor is equal to: 100 divided by the solids percentage of the finish. For Hard Coat 19, 100/19% = 5 coats.

- Reflection 22. With 22% solids, this finish is a flexible balance for many programs. It offers an excellent level of gloss and protection, is easier to apply than Reflection 25, and usually needs about 4-5 coats of finish for optimal performance.

3. No Buffing Program

For programs that employ a simple scrub-and-recoat procedure with no interim maintenance, customers can choose either Dual 18 High/Low Speed Super Gloss Floor Finish for standard traffic areas, or Ure-Coat Urethane Fortified Seal & Finish for industrial floors or areas with higher foot traffic.

Is a “green” floor finish required?

Certain buildings such as those with LEED or green requirements necessitate the use of “green” finishes. If this is the case your choices will be limited to finishes that have independent Green Certification, and often include VOC level considerations and exclusion of heavy metals. Choose e.Coat Zinc Free Floor Finish.

Certain buildings such as those with LEED or green requirements necessitate the use of “green” finishes. If this is the case your choices will be limited to finishes that have independent Green Certification, and often include VOC level considerations and exclusion of heavy metals. Choose e.Coat Zinc Free Floor Finish.

To sum it up, all Nyco floor finishes are high gloss, extremely durable, scuff and black mark resistant, and meet or exceed ASTM D-2047 standards for Slip Resistance. The variables that will differentiate which finish should be recommended include:

- How frequently the customer performs floor maintenance

- What type of equipment they use

- The skill level of their labor force

- Environmental conditions such as temperature and humidity

- Whether Green Certification is required

For additional information or training on how to select the right floor finish for your building and program, call us at 800-752-4754 or contact our customer service department.